Новини за продукти

-

Какво правят U-болтовете с листови пружини?

U-болтовете на листовите пружини, известни още като U-болтове, играят ключова роля в системата за окачване на превозните средства. Ето подробно обяснение на техните функции: Фиксиране и позициониране на листовата пружина Роля: U-болтовете се използват за здраво закрепване на листовата пружина към оста (оста на колелото), за да се предотврати деформацията на листовата пружина...Прочетете още -

Колко дълго издържат листовите пружини? Разбиране на техния живот и поддръжка

Листовите ресори са критичен компонент на окачването на превозното средство, често срещани в камиони, ремаркета и по-стари модели автомобили. Основната им роля е да поддържат теглото на превозното средство, да абсорбират пътните удари и да поддържат стабилност. Въпреки че тяхната издръжливост е добре известна, животът им варира значително...Прочетете още -

Каква е функцията на пружинната втулка?

Пружинната втулка е композитен компонент, който съчетава функциите на еластични елементи и втулки в механичните системи. Тя се използва широко в сценарии като абсорбиране на удари, буфериране, позициониране и намаляване на триенето. Основните ѝ функции могат да бъдат обобщени, както следва: 1. Абсорбиране на удари ...Прочетете още -

Как да измерим U-образен болт за листова пружина?

Измерването на U-образен болт за листова пружина е важна стъпка за осигуряване на правилното прилягане и функционалност в системите за окачване на превозни средства. U-образните болтове се използват за закрепване на листовата пружина към оста и неправилните измервания могат да доведат до неправилно подравняване, нестабилност или дори повреда на превозното средство. Ето една стъпка...Прочетете още -

Предпазни мерки при използване на листови пружини

Като важен еластичен елемент, правилното използване и поддръжка на листовите пружини пряко влияят върху производителността и безопасността на оборудването. Следните са основните предпазни мерки при използване на листови пружини: 1. Предпазни мерки при монтаж * Проверете дали има дефекти като пукнатини и ръжда по...Прочетете още -

Предизвикателствата и възможностите на Leaf Spring

Въпреки че пазарът на листови пружини предлага значителни възможности за растеж, той е изправен и пред няколко предизвикателства: Високи първоначални разходи: Значителната първоначална инвестиция, необходима за внедряване на решения за листови пружини, може да бъде пречка за някои организации. Технически сложности: Сложността на интеграцията...Прочетете още -

Анализ на пазара на автомобилни листови пружини

Пазарът на автомобилни листови пружини се оценява на 5,88 милиарда щатски долара през текущата година и се очаква да достигне 7,51 милиарда щатски долара през следващите пет години, регистрирайки годишен темп на растеж от около 4,56% през прогнозния период. В дългосрочен план пазарът се движи от увеличението на търсенето...Прочетете още -

Как технологичният напредък трансформира системите за окачване?

Технологичният напредък е оказал значително влияние върху дизайна и функционалността на автомобилните системи за окачване с листови пружини, правейки ги по-ефективни и адаптивни към съвременните изисквания на превозните средства. Иновациите в материалознанието, по-специално разработването на високоякостна стомана и...Прочетете още -

Ръководство за производствения процес на листови ресори - Пробиване на отвори за закрепване на дистанционни елементи за броня (част 4)

Ръководство за производствения процес на листови ресори - Пробиване на отвори за закрепване на дистанционни елементи за броня (част 4) 1. Определение: Използване на оборудване за щанцоване и инструменти за пробиване на отвори в определените позиции за закрепване на подложки против скърцане / дистанционни елементи за броня в двата края на плоската пружинна стоманена греда. Обикновено...Прочетете още -

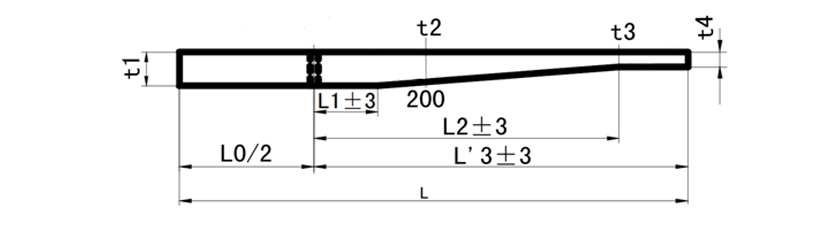

Ръководство за производствения процес на листови пружини - стесняващи се (дълги стесняващи се и къси стесняващи се) (Част 3)

Ръководство за производствения процес на листови пружини - стесняване (дълго стесняване и късо стесняване) (Част 3) 1. Определение: Процес на стесняване/валцоване: Използване на валцова машина за стесняване на плоски пружинни пръти с еднаква дебелина в пръти с различна дебелина. Обикновено има два процеса на стесняване: дълго стесняване...Прочетете още -

Ръководство за производствения процес на листови пружини - пробиване на отвори (част 2)

1. Определение: 1.1. Пробиване на отвори Пробиване на отвори: използвайте оборудване за щанцоване и инструменти за пробиване на отвори на желаната позиция в плоския прът от пружинна стомана. Обикновено има два вида методи: студено щанцоване и горещо щанцоване. 1.2. Пробиване на отвори Пробиване на отвори: използвайте пробивни машини и ...Прочетете още -

Ръководство за производствения процес на листови пружини - рязане и изправяне (част 1)

1. Определение: 1.1. Рязане Рязане: нарязване на плоски пръти от пружинна стомана на необходимата дължина съгласно изискванията на процеса. 1.2. Изправяне Изправяне: регулиране на страничното огъване и плоското огъване на отрязания плосък прът, за да се гарантира, че кривината на страната и равнината отговаря на производствените изисквания...Прочетете още